► Stellantis reveals ‘IBIS’ battery tech

► Embeds inverters and chargers into battery modules

► Designed to improve weight, range and packaging

Stellantis claims it’s got a ‘game changer’ of a battery technology on its hands: something it calls the Intelligent Battery Integrated System.’

The automotive group has worked with partners like Saft on the research project, aiming to develop ‘a more efficient, sustainable and cost-effective energy storage and electric conversion’ setup.

‘With a conventional powertrain, you have a DC battery and it’s necessary to have specific conversion components to transform DC current to three-phase AC current to control the torque of the electric motors,’ says Francis Roy, IBIS project manager. ‘With a standard inverter, you’ve got a very high commutation frequency and the quality of this three-phase current is not very good. The harmonics that result produce losses in the electric motor.’

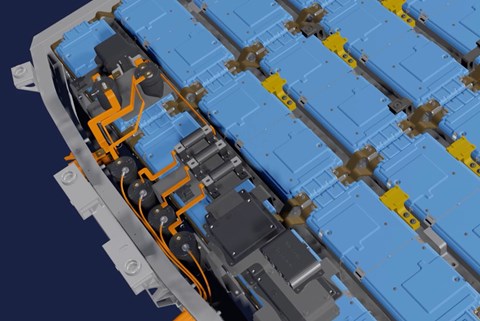

With IBIS, Roy says the standard inverter and charger have been removed, instead embedding them into the battery pack. Doing so, and applying them to each battery module, allows more detailed control of each module and deployment of its charge.

‘In a way, it’s like we’re playing piano with the modules,’ says Anne Laliron, senior vice president for technology research at Stellantis. ‘You’re not using all the modules all of the time and your battery is not limited by its weakest modules. It’s a way to increase the lifespan of the battery.’

Laliron also claims the technology improves a car’s residual value, because it can hold a bigger range for a longer period. ‘It also unlocks for us the possibility of mixing the chemistries inside the battery pack, adding the best chemistry depending if we want to have more range or reduce cost,’ she says.

Stellantis isn’t the only major car maker to be working on a similar kind of battery control. Porsche, for example, has been working on similar technology. Mercedes-Benz, too, is applying individual module controls to battery packs in a move it calls ‘cylinder de-activation for batteries.’ However, Stellantis engineers claim they are further ahead; while Porsche and Mercedes are still at the theoretical phase, its team have implemented the IBIS battery tech into its first prototype aboard a Peugeot e-3008.

In the case of that demo car, Stellantis says the e-3008 charges around 15 per cent faster, power from the electric motor has increased by a similar percentage and around 40kg has been shed via fewer components and changes in battery chemistry.

Stellantis and its partners are powering ahead to production, claiming that the technology will be implemented in its cars by the end of the decade.